1. The term line speed usually refers to the slaughter line (aka evisceration line) and the rate at which animals are slaughtered. The USDA sets an upper limit for this line based on the maximum number of animals for which inspectors can conduct the required post-mortem examination.

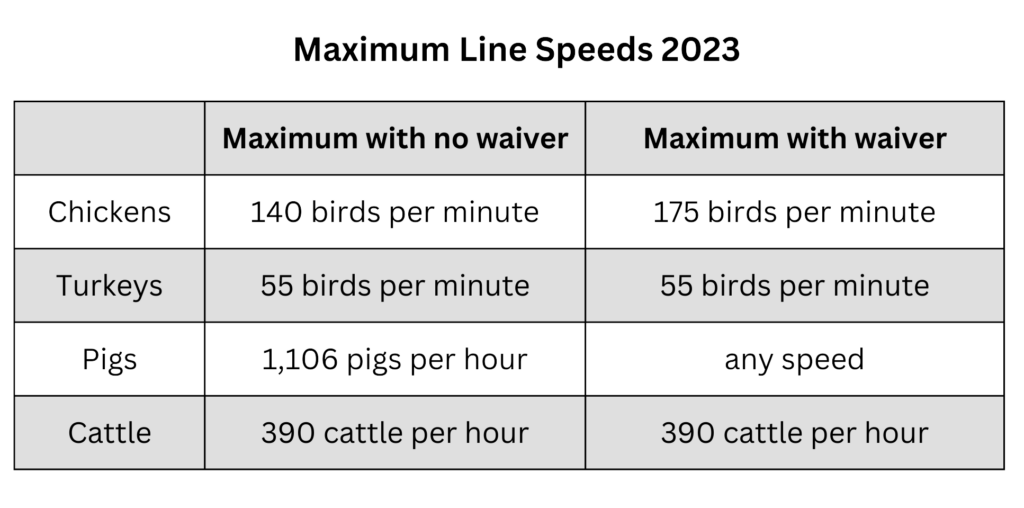

2. USDA regulations set maximum slaughter line speeds by species: chickens – 140 birds per minute; turkeys – 55 birds per minute; pigs – 1,106 per hour; and cattle – 390 per hour.

3. Some pig and chicken slaughter plants have been given waivers by the USDA to operate slaughter line speeds faster than set by regulations.

4. Slaughter lines feed carcasses onto multiple processing lines where workers perform cutting and de-boning tasks. These processing lines generally operate at slower speeds than slaughter lines.

5. The USDA does not regulate processing line speeds.

In a slaughterhouse, the line generally refers to the initial operations of the actual slaughter and cutting up of the animal.[1] On the line, animals are stunned, killed, blood is drained (exsanguination), and organs are removed (evisceration).[2] It is a highly mechanized process that generally proceeds with animals hung on fast-moving hooks or chains; once eviscerated, the carcasses move on conveyor belts with workers rapidly performing well-defined, repetitive tasks. The first part of the process is sometimes referred to as an evisceration line, and the further cutting, deboning, and packaging is usually called a processing line, or a secondary line.[3,4]

U.S. Government Accountability Office (December 2017) Workplace Safety and Health: Better Outreach, Collaboration, and Information Needed to Help Protect Workers at Meat and Poultry Plants, GAO-18-12, p. 6, 38. [“Meat and poultry slaughter and processing generally occurs along a “disassembly line,” on which workers and machines produce various cuts of meat. These lines can include live hang in poultry plants, evisceration lines, and “cone” lines where deboning occurs. The Food Safety and Inspection Service (FSIS) sets maximum evisceration line speed in order to ensure its inspectors can effectively perform their inspection procedures.”]

Note: Animals are not always immediately stunned in the slaughter process. For livestock, ineffective stunning is usually due to human error, mechanical malfunction, or improper stun gun or CO2 chamber settings. Poultry are often paralyzed by the stun bath while remaining sensitive to pain, and some birds miss the stun bath entirely.

79 Fed Reg 49566, 49599 (2014) USDA FSIS Modernization of Poultry Slaughter Inspection. [“…inspection line speed does not directly impact plant employees in further stages of an establishment (e.g., on the processing line).”]

National Chicken Council, Poultry Processing Line Speeds: An Infographic Overview, https://www.chickencheck.in/infographics/poultry-line-speeds/

Line speed is usually used in reference to the slaughter or evisceration line. The USDA sets an upper limit for this line. That limit is based on the maximum number of animals for which inspectors can conduct the required post-mortem examination. The maximum line speeds vary depending on the number of inspectors and the size and species of the animals.[1,2] For poultry, the line speed refers to the number of birds killed and inspected per minute. For pigs and cattle, it is calculated as animals slaughtered and inspected per hour.

Livestock: 9 CFR § 310.1 Extent and time of post-mortem inspection; post-mortem inspection staffing standards

Poultry: 9 CFR § 381.69 Maximum line speed rates under the New Poultry Inspection System

When referring to line speeds, it is necessary to distinguish between slaughter lines and processing lines (also called secondary lines). The slaughter line usually feeds carcasses onto multiple processing lines where workers perform cutting and de-boning tasks.[1] These processing lines generally operate at slower speeds than slaughter lines.[2]

National Chicken Council, Poultry Processing Line Speeds: An Infographic Overview.

National Chicken Council (July 23, 2020) Four Things You Should Know about ‘Poultry Line Speeds’, https://www.nationalchickencouncil.org/four-things-you-need-to-know-about-poultry-line-speeds/ [“Second processing lines, where workers debone and cut up chicken parts, remain about one-fifth of the speed of the evisceration line.”]

Yes. Maximum slaughter line speeds are set by the USDA in the Code of Federal Regulations, and they are based on the number of animals that the Food Safety and Inspection Services (FSIS) inspectors are thought to be able to effectively inspect for disease.[1-3] The USDA has no authority over processing line speeds and regards the two lines as independent of each other.[4]

Poultry: 9 CFR § 381.69 Maximum line speed rates under the New Poultry Inspection System.

Livestock: 9 CFR § 310.1 Extent and time of post-mortem inspection; post-mortem inspection staffing standards.

See in Government section, Slaughterhouse Line Speed Regulations

79 Fed Reg 49566 (2014) USDA FSIS Modernization of Poultry Slaughter Inspection. [“FSIS believes a key distinction should be made between processing line speed, inspection line speed, and daily production volume.” at 49598] [“…inspection line speed does not directly impact plant employees in further stages of an establishment (e.g., on the processing line).” at 49599]

Maximum slaughter line speeds are set by regulations.[1,2] However, as of March, 2024, the USDA has issued waivers to 45 chicken slaughter plants, allowing them to operate at speeds up to 175 birds per minute.[3] As of November 2024, six hog slaughter plants were operating under provisional waivers, allowing the plants to set their own line speed.[4]

Poultry: 9 CFR § 381.69 Maximum line speed rates under the New Poultry Inspection System

Livestock: 9 CFR § 310.1 Extent and time of post-mortem inspection; post-mortem inspection staffing standards

USDA, FSIS (2024) Modernization of Poultry Slaughter Inspection. https://www.fsis.usda.gov/inspection/inspection-programs/inspection-poultry-products/modernization-poultry-slaughter

USDA FSIS (November 8, 2024) Modernization of Swine Slaughter Inspection, NSIS Conversion Numbers. https://www.fsis.usda.gov/inspection/inspection-programs/inspection-meat-products/modernization-swine-slaughter-inspection

Probably the larger plants do, though we don’t have a lot of data on this. Decisions to run at faster line speeds can be based on the size of the plant, its infrastructure, and customer demand, as well as the plant’s ability to comply with inspection safety regulations.[1,2]

For the poultry plants that have been issued waivers to operate at slaughter line speeds in excess of 140 bpm, the USDA notes that of the 11 establishments recently visited: 4 plants had evisceration line speeds of ≤145 bpm, 3 plants ran between >145 and ≤175 bpm, and 4 plants ran at 175 bpm.[3]

At present, 6 hog slaughter plants have waivers to operate slaughter above the normal maximum speed of 1,106 hogs per hour. A study on the impacts to worker safety reported that the six establishments with waivers ranged from the regulatory maximum of 1,106 head per hour (HPH) to “up to 350 HPH faster.”[4] An earlier report from an Iowa State researcher also suggested that top rates for the plants with waivers were about 1,450 pigs per hour.[5]

USDA, FSIS (2014) 79 Fed Reg 49566, 49567, Modernization of Poultry Slaughter Inspection [“Establishments determine their line speeds based on their equipment and facilities, bird size and flock conditions, and their ability to maintain process control when operating at a given line speed.”]

USDA, FSIS (2019) 84 Fed Reg 52300, Modernization of Swine Slaughter Inspection. [“…revoking maximum line speeds and authorizing establishments to determine their own line speeds based on their ability to maintain process control for preventing fecal contamination and meeting microbial performance measures for carcasses during the slaughter operation.”]

USDA FSIS (January 9, 2025) Poultry Processing Line Speed Evaluation Study, Harris-Adamson, C. et al., (Researchers, Univ. of California, San Francisco), p. 16.

USDA FSIS (January 9, 2025) Swine Processing Line Speed Evaluation Study, Harris-Adamson, C. et al., (Researchers, Univ. of California, San Francisco), p. 17.

Dermot Hayes (2021) Economic Impact of the Recent District Court Ruling Regarding Line Speeds on the U.S. Pork Industry, p. 3. [“These plants operate between approximately 1,225 and 1,450 head per hour… Collectively, these plants harvest one fifth of the approximately 130 million hogs annually harvested nationally.”]

Yes. Given the capacity of typical large slaughterhouses, calculations of the number of animals slaughtered show that many large plants have multiple slaughter lines.[1-3]

A typical large poultry plant can slaughter about 470 birds per minute. A typical large hog slaughterhouse can slaughter about 2,500 hogs per hour. A typical cattle slaughterhouse can slaughter about 615 cattle per hour. These figures are all well above the numbers that can be slaughtered on a single line at maximum speed.

USDA, FSIS (2014) 79 Fed Reg 49566, 49616 Modernization of Poultry Slaughter Inspection. [“FSIS ADRS 2010 records indicated that there were 663 line-shifts in 270 establishments that slaughter young chickens and turkeys.” (Line-shifts equals the number of lines multiplied by the number of 8-hour work shifts)]

See, Slaughterhouse Capacities

Poultry processing lines (where the birds are deboned and cut up for packaging) generally run at about 35 to 40 birds per minute.[1-4]

We do not have data on secondary line speeds in livestock slaughter. And it is difficult to generalize since there are more cutting procedures in eviscerating and deboning livestock than poultry, e.g., abdomen cutting, head removal, hide removal, and hock cutting. The lines for each procedure may vary. Although not generally used in the U.S. at present, robotic systems are being introduced to these traditionally manual jobs and may shed some light on the different processing lines speeds.[5] The purported advantages of robotic technology appear to be better sanitation and fewer workers, thereby reducing worker injuries and presumably increasing profitability. It is not clear if the processing line speeds would be affected.[6]

Ramsey, J., et al., (2015) U.S. Dept. of Health & Human Services, CDC, NIOSH, Evaluation of Musculoskeletal Disorders Among Employees at a Poultry Processing Plant, Report No. 2014-0040-3232, p. 2. [Notes secondary processing line speeds of 40 bpm]

Musolin, K., et al., (2014) U.S. Dept. of Health & Human Services, CDC, NIOSH, Evaluation of Musculoskeletal Disorders and Traumatic Injuries Among Employees at a Poultry Processing Plant, Report No. 2012-0125-3204, p. 2. [Notes secondary processing line speeds of 35 bpm]

National Chicken Council (July 23, 2020) Four Things You Should Know about ‘Poultry Line Speeds.’ [Notes that secondary line speeds typically run at “one-fifth of the speed of the evisceration line.” At a probable slaughter line speed of 175 birds per minute, one fifth equals 35 bpm. Four lines at 35 bpm = line speed of 140 bpm. It is presumably not coincidental that the increased “waiver” slaughter line speed of 175 bpm is a 35 bpm increase, or one additional processing line.]

United Food and Commercial Workers International Union (UFCW) (September 8, 2020) Three Things You Should Know About Poultry Line Speeds. https://www.ufcw.org/three-things-you-should-know-about-poultry-line-speeds/ [Notes that processing workers handle 35 to 45 birds per minute]

Kim, J., et al., (2023). Robot Technology for Pork and Beef Meat Slaughtering Process: A Review. Animals (Basel), 13(4), 651, pp. 3-5. [Robotic systems: pig abdomen cutting (350-650 head per hour); pig rectal removal (550-650 head per hour); pigs, cattle & sheep hock cutting (450 head per hour)]

Romanov, D., et al., (2022). Towards human-robot collaboration in meat processing: Challenges and possibilities. Journal of Food Engineering, 331, 111117–, p. 5.

There are many reports that find there is a correlation. Most specific information comes from the workers themselves. In a civil action challenging the USDA’s program to increase poultry slaughter line speeds, in evidence were studies, reports, and declarations from workers showing that faster line speeds “increase the number of repetitive motions performed by poultry workers, which in turn substantially increases the risk of injury.”[1]

A joint federal agency report found that a high percentage of frontline workers at a hog slaughterhouse noticed “changes during the past year that affected their job or safety and health concerns. Employees reported that after a chain speed increase, it was harder to keep up with work, they had experienced more pain, and some job tasks had fewer people assigned than needed.[2,3]

United Food and Commercial Workers vs. USDA, case 1:20-cv-02045, 532 F. Supp. 3d (8/20/21) (D.D.C.) p. 7.

Grant, M. P., et al., (2024) U.S. Dept. of Health & Human Services, CDC, NIOSH, Evaluation of Ergonomic Risks, Musculoskeletal Disorders, and Peracetic Acid Exposure Among Employees at a Pork Processing Plant in Michigan, p. B-13.

See, Line Speed Impacts on Slaughter and Processing Workers [Page includes results from two recent USDA studies on line speeds and worker safety.]

There are some subjects that do not require academic research. The entire slaughter process from loading to transport to animal movement to death is already brutal for farmed animals.

Common sense suggests that faster line speeds increase animal pain and suffering. There are more transport trucks moving on tighter schedules. Animals in slaughter queues must be moved more quickly in larger groups. Each preparatory slaughter step must occur at a faster pace. Workers on the slaughter line have less time to attend to each animal. Animals improperly stunned will inevitably get less attention. An assumption that the industry would adjust its processes to mitigate animal pain and suffering is not in line with the economics of meat processing.