According to the U.S. Government Accountability Office (GAO), “Meat and poultry slaughter and processing is one of the most hazardous industries in the United States.”[1] The U.S. Dept of Labor also acknowledges that “there are many serious safety and health hazards in the poultry processing industry.”[2]

U.S. Government Accountability Office (2017) Workplace Safety and Health: Better Outreach, Collaboration, and Information Needed to Help Protect Workers at Meat and Poultry Plants, Report 18-12, GAO Highlights.

U.S. Dept of Labor, Occupational Safety and Health Administration (OSHA) Safety and Health Topics, Poultry Processing, https://www.osha.gov/poultry-processing

Fast, repetitive, and strenuous work.

Dangerous machinery including fast-moving shackle hooks and scalding tanks.

Working with knives and scissors.

Slippery floors and equipment due to water, blood, and fat.

Close proximity of workers.

Extreme temperatures.

High noise levels.

Hazardous chemicals including antibacterials.

Biological hazards from animals, blood, and feces.[1-3]

U.S. Dept of Labor, Occupational Safety and Health Administration (OSHA) Safety and Health Topics, Poultry Processing, https://www.osha.gov/poultry-processing

OSHA (October 15, 2024) Memorandum for Regional Administrators, Re: Inspection Guidance for Animal Slaughtering and Processing Establishments.

https://www.osha.gov/laws-regs/standardinterpretations/2024-10-15 [This recent memorandum provides a surprisingly thorough overview of the risk factors, including inadequate medical facilities, Inadequate toilet and sanitary facilities, and night work for sanitation crews, among others.]U.S. Government Accountability Office (2016) Workplace Safety and Health: Additional Data Needed to Address Continued Hazards in the Meat and Poultry Industry, Report 15-337, p. 1.

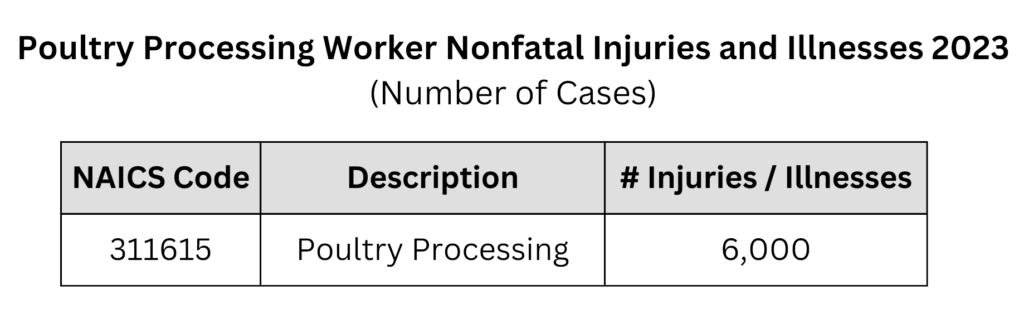

The Bureau of Labor Statistics (BLS) reports that in 2023, there were a total of 6,000 nonfatal occupational injuries and illnesses (designated as recordable cases) for workers in the poultry slaughter and processing industry.[1]

U.S. Dept of Labor, Bureau of Labor Statistics Injuries, Illnesses, and Fatalities, Number of cases – detailed industry level 2023 (Table 2 – NAICS 311615) https://www.bls.gov/iif/nonfatal-injuries-and-illnesses-tables.htm#interactive

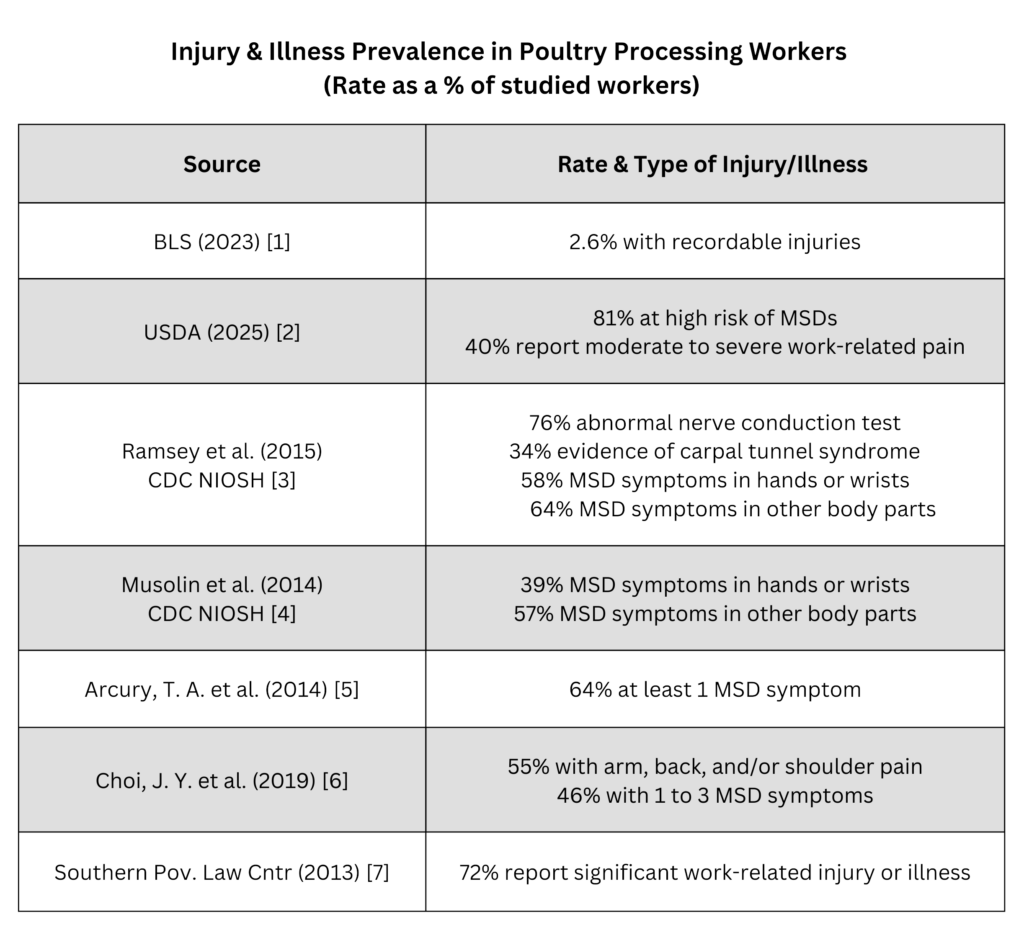

The incidence rate (of recordable cases) in 2023 for workers in the poultry slaughtering and processing industry was 2.6 per 100 workers.[1]

U.S. Dept of Labor, Bureau of Labor Statistics Injuries, Illnesses, and Fatalities, Incidence rates – detailed industry level 2023 (Table 1 – NAICS 311615)

The 2023 incidence rate of 2.6 per 100 poultry processing workers is similar to that of 2.7 per 100 workers in all goods-producing industries.[1]

U.S. Dept of Labor, Bureau of Labor Statistics Injuries, Illnesses, and Fatalities, Incidence rates – detailed industry level 2023 (Table 1)

https://www.bls.gov/iif/nonfatal-injuries-and-illnesses-tables.htm#interactive

For BLS statistics purposes, a “recordable” injury or illness case is one that results in:

Death.

Loss of consciousness.

Days away from work.

Restricted work activity or job transfer.

Medical treatment beyond first aid.

Significant work-related injuries or illnesses that are diagnosed by a physician or other licensed health care professional.[1]

Additional criteria that can result in a recordable case include contamination from another person’s blood or other infectious material, tuberculosis infection, and hearing loss. Naturally, not all recordable injuries are actually recorded. They may be unreported by employees or unrecorded by employers and thus are not counted in the BLS statistics.[2]

U.S. BLS (2023) Injuries, Illnesses, and Fatalities, BLS OSH Definitions. https://www.bls.gov/iif/definitions/occupational-safety-and-health-definitions.htm

See, Injury Undercounts to Animal Ag Workers

Evidence of significant underreporting of injuries and illnesses experienced by poultry processing workers is seen in both government and independent research into the rates of injury at processing plants.

Injury and illness undercounts are understood to be pervasive throughout the industry.[8]

U.S. Dept of Labor, Bureau of Labor Statistics Injuries, Illnesses, and Fatalities, Number of cases – detailed industry level, 2023 (Table 2 – NAICS 311615) [For the definition of “recordable injuries” see, question above. The BLS reports nationwide rates based on the Survey of Occupational Injuries and Illnesses (SOII) which is a survey of business establishments.(BLS Survey of Occupational Injuries and Illnesses: Data sources.

USDA FSIS (January 9, 2025) Poultry Processing Line Speed Evaluation Study, Harris-Adamson, C. et al., (Researchers, Univ. of California, San Francisco), p. 46. [This USDA study analyzed injury rates to workers in 11 large poultry processing plants that were intermittently running at line speeds above the statutory maximum.]

Ramsey, J. et al., (2015) U.S. Dept. of Health & Human Services, CDC, NIOSH, Evaluation of Carpal Tunnel Syndrome and Other Musculoskeletal Disorders among Employees at a Poultry Processing Plant, Report No. 2014-00403232, p. 13. [“Sixty-six percent (20/30) reported at least one work-related injury or illness that met OSHA 300 reporting criteria…but only one was reported on the 2013 OSHA Logs.” at p. 13. Study conducted by the CDC on 342 full-time workers at a Maryland processing plant. at p. 1]

Musolin et al. (2014) U.S. Dept. of Health & Human Services, CDC, NIOSH, Evaluation of Musculoskeletal Disorders and Traumatic Injuries Among Employees at a Poultry Processing Plant, Report No. 2012-0125-3204, p. i. [“Thirty-nine percent of participants had hand or wrist symptoms at both baseline and follow up evaluations. Fifty-seven percent of participants reported at least one musculoskeletal symptom (not including hand or wrist symptoms) at both baseline and follow-up evaluations.” Study conducted by the CDC on ~1,560 full-time workers at a South Carolina processing plant. at p. 2]

Arcury, T. A., et al., (2014). Work Organization and Health Among Immigrant Women: Latina Manual Workers in North Carolina. American Journal of Public Health (1971), 104(12), 2445–2452, Table 1, p. 2448. [Reports 45.7% had 1 to 3 MSD symptoms and 18.5% had 4 to 6 symptoms. This was a 2-year study of 173 female poultry processors in 4 North Carolina counties. at p. 2446]

Choi, J. Y. & Constance, D. H. (2019) Marshallese Migrants and Poultry Processing, Journal of Rural Social Sciences, Vol 34., Issue 1, p. 17. [Convenience sample reporting on 198 Marshallese workers (Pacific Islander groups) at an Arkansas processing plant]

Southern Poverty Law Center & Alabama Appleseed (2013) Unsafe at any Speeds, pp. 5-7 [“Seventy-two percent of the participants in this survey of 302 current and former poultry workers in Alabama described suffering a significant work-related injury or illness while working in the industry.”]

See, Undercounts of Injury and Illness to Animal Ag Workers

The most common ailments for workers in the industry are musculoskeletal disorders (MSDs) which are cumulative trauma injuries like carpal tunnel or tendonitis that develop through repeated stress over time. Poultry processing work requires highly repetitive, forceful movements to disassemble the animals. “Since cumulative trauma damages internal parts of the body—muscles, tendons, bones, and nerves—it may not be immediately apparent and is often not treated until damage is permanent and disabling.”[1]

In an oft-cited study of a poultry processing plant in South Carolina, a joint federal agency report determined that 42% of workers had evidence of carpal tunnel syndrome; 39% had MSD hand or wrist symptoms at both initial and follow-up evaluations; and 57% reported at least one MSD symptom (not including hand or wrist).[2]

In the study it was established that the majority of hand-intensive, repetitive tasks were in “cone” lines for deboning the chicken (secondary processing). Each of the five cone lines ran at 35 birds per minute, or almost one bird every two seconds.[3]

Currently, many large poultry plants, including at Tyson Foods, Wayne Farms, Pilgrim’s Pride, and Mountaire Farms have obtained waivers to operate their line speed at the increased rate of 175 birds per minute.[4,5] One legal brief claims to have affidavits from USDA inspectors describing the task of inspecting nearly three birds per second as “a dizzying blur.”[6] And while workers in the cut-up and packaging lines do not work at the rate of the initial line speed, there are concerns that increased speeds put even more pressure on the secondary processing lines.[7]

Indeed, a study commissioned by the USDA on the impacts of increased line speeds on workers at 11 poultry processing operations found that the vast majority (81%) of workers had an “unacceptably high MSD risk” regardless of the evisceration line speed.[8]

Human Rights Watch (2019) When We’re Dead and Buried, Our Bones Will Keep Hurting: Workers’ Rights Under Threat in US Meat and Poultry Plants. p. 35.

Musolin et al., (2014) U.S. Dept. of Health & Human Services, CDC, NIOSH, Evaluation of Musculoskeletal Disorders and Traumatic Injuries Among Employees at a Poultry Processing Plant, Report No. 2012-0125-3204, p. 26.

Musolin et al., (2014). p. 2. [Most of the first processing jobs are automated.]

National Employment Law Project (2020) USDA Allows Poultry Plants to Raise Line Speeds, Exacerbating Risk of COVID-19 Outbreaks and Injury, Policy Brief, p. 1. https://s27147.pcdn.co/wp-content/uploads/Policy-Brief-USDA-Poultry-Line-Speed-Increases-Exacerbate-COVID-19-Risk.pdf

USDA Food Safety and Inspection Service (November 2024) Modernization of Poultry Slaughter Inspection. https://www.fsis.usda.gov/inspection/inspection-programs/inspection-poultry-products/modernization-poultry-slaughter

Humane Society et al. vs. USDA (2020) Case No. 3:20-cv-1395, U.S. Dist. Ct Northern District California, p. 3, 20.

Brian Ronholm (2018) Eschewing obfuscation on poultry slaughter line speed, Food Safety News https://www.foodsafetynews.com/2018/01/eschewing-obfuscation-on-poultry-slaughter-line-speed/#:~:text=The%20slaughter%20practices%20described%20above,lines%20up%20to%20175%20bpm

USDA FSIS (January 9, 2025) Poultry Processing Line Speed Evaluation Study, Harris-Adamson, C. et al., (Researchers, Univ. of California, San Francisco), p. 46.

Poultry processing workers are exposed to a variety of chemicals, including ammonia and chlorine (used in refrigeration systems) as well as antimicrobial chemicals sprayed on the meat or used to clean equipment.[1]

Currently, peracetic acid (PAA) is one of the most common antimicrobials used to reduce the incidence of Salmonella and Campylobacter in poultry and is applied directly to the bird as well as being used to clean equipment. The chemical is corrosive and unstable and can be an irritant to the upper respiratory tract, eyes, and skin. Currently, there is no OSHA limit on the acute or long-term exposure limit of PAA for workers, even though other governing bodies have set exposure limits.[2] A study commissioned by the USDA on the impacts of increased line speeds on workers at 11 poultry processing operations found that airborne PAA concentrations were considered above guidelines for “1 in 5 jobs that were sampled, indicating that current risk mitigation efforts are insufficient.”[3]

Workers also suffer in chemical accidents. In 2021, six poultry workers were killed by a liquid nitrogen leak at a poultry processing plant in Georgia, and there were three subsequent chemical spills within fourteen months at the same plant.[4,5] In 2011, 152 workers at an Arkansas poultry plant were reported as hospitalized from effects of chlorine gas.[6] And in a 2016 survey of poultry processing workers in Arkansas, one out of ten workers said that they had been present during chemical spills or gas leaks at their places of employment.[7]

U.S. Dept. of Labor, OSHA, Poultry Processing Industry eTool, Plant-Wide Hazards, Chemical Hazards, https://www.osha.gov/etools/poultry-processing/plant-wide-hazards/chemical-hazards

Dittoe, D.K. et al., (2019). The Addition of ViriditecTM Aqueous Ozone to Peracetic Acid as an Antimicrobial Spray Increases Air Quality While Maintaining Salmonella Typhimurium, Non-pathogenic Escherichia coli, and Campylobacter jejuni Reduction on Whole Carcasses. Frontiers in Microbiology, 9, 3180–3180, p. 2.

USDA FSIS (January 9, 2025) Poultry Processing Line Speed Evaluation Study, Harris-Adamson, C. et al., (Researchers, Univ. of California, San Francisco), p. 7. [The American Conference of Governmental Industrial Hygienists (ACGIH) has established a Threshold Limit Value-Short-Term Exposure Limit (TLV-STEL) of 0.4 ppm for peracetic acid (PAA).]

U.S. Dept. of Labor, OSHA News Release Region 4 (April 2, 2021) OSHA continues investigation into January fatal incident at Foundation Food Group Services in Gainesville.

Paola Suro (2022) It’s imperative that companies put people over production’ | Three chemical spills at Gainesville poultry plant in 14 months. 11Alive.com News. https://www.11alive.com/article/news/local/gainesville-poultry-plant-chemical-spills/85-a0fcd917-537c-43a1-b1b1-f307e21c9492

Meza, F. et al., (2013) CDC, NIOSH, Evaluation of Health Effects of a Chlorine Gas Release in a Poultry Processing Plant—Arkansas. Health Hazard Evaluation Report 2011-0128-3166 https://www.cdc.gov/niosh/hhe/reports/pdfs/2011-0128-3166.pdf

The Northwest Arkansas Workers’ Justice Center (2016) Wages and Working Conditions in Arkansas Poultry Plants, p. 29.

Yes. The agency is required to be notified of severe injuries, defined as an amputation, in-patient hospitalization, or loss of an eye. In 2023, federal OSHA received 49 such reports from poultry processors, 19 of which were categorized as amputations, defined as complete or partial loss of a finger.[1]

Not all serious injuries are reported to federal OSHA, however. The agency has authorized more than 20 states to operate their own occupational safety and health agencies. These state plans must be at least as effective as federal OSHA, but OSHA tallies “do not include incidents under state plan jurisdiction.”[2]

Of the states that currently report to state OSHA Plan agencies, several rank at the top of poultry slaughter states.[3] Thus, it is likely that the number of severe injuries that are reported only to the state agencies (and thus are not made publicly available on the federal OSHA website) are as high, or higher, than those reported by federal OSHA.[4]

U.S. Dept. of Labor, Occupational Safety and Health Administration (OSHA), Severe Injury Reports. [Data set for 2023 using NAICS codes: 311615 “poultry processing”]

Severe Injury Reports. [“These data will be updated periodically and represent incidents under federal OSHA jurisdiction only.”]

USDA NASS (2024) Poultry Slaughter Summary, p. 19. [e.g., Arkansas, North Carolina, South Carolina, and Maryland]

Debbie Berkowitz & Patrick Dixon (March 30, 2023) An average of 27 workers a day suffer amputation or hospitalization, according to new OSHA data from 29 states, Economic Policy Institute.

https://www.epi.org/blog/an-average-of-27-workers-a-day-suffer-amputation-or-hospitalization-according-to-new-osha-data-from-29-states-meat-and-poultry-companies-remain-among-the-most-dangerous/ [Report lists the 21 states that do not report severe injuries to federal OSHA , see fn. 1]